Our Equipments

Home » Quality

QUALITY CONTROL

Quality in UMW is an understood fact and an ever-evolving process

At UMW, we believe in putting “Quality First” as our core value- Our QM system has a

singular focus on prevention instead of error correction. That is why we take the

minutest issues with utmost seriousness to ensure fasteners are manufactured in

compliance with codes & specifications . We are committed to deliver customers

orders within the stipulated time, as it plays a vital role in establishing a company as a

reliable brand. Our wide distribution network and flexibility in production and

workforce enable us to meet this objective. We have easy access to our raw materials

and thus are capable to fulfill bulk and immediate requirements of our clients.

TORQUE TESTING MACHINE

LIST OF TESTING EQUIPMENTS

| Sr. No | Machine/Equipment Names | Make | Range | Testing Parameters / Usage |

| 01 | Digital Rockwell Hardness Tester | FIE | 1OOKGF / 150KGF | To check the Hardness of any material in HRC/HRB Scale digitally. |

| 02 | Universal Testing Machine/ With Computer Software | FIE | 0-1000KN | To evaluate the Physical Property of any material by performing tests such as Tensile Strength, Yield Strength, Elongation% ,RA%, Proof Load and Compression Load. |

| 03 | Rockwell Hardness Tester | FIE | 150KGF | To check the Hardness of any material in HRC/HRB Scale analogly. |

| 04 | Positive Material Identification Machine | THERMO FISHER | 25 Element | To Check Chemical Composition of Material |

| 05 | Spectro Machine | OXFORD | 28 Element | To Check Chemical Composition of Material |

| 06 | Impact Testing Machine / Digital Temperature Controller | FIE | 0-300 J | To check the shock absorption value at a specific temperature by conducting Impact Testing. |

| 07 | Bolt Torque Tension Testing Machine | SUSHMA | 0-5000 Nm | To check Torque/Tensioning of an assembly consists k-factor , Clamp Load, Nut Rotation Angle and Torque. |

| 08 | Coating Thickness Gauge | ELCOMETER | 0-1350 μm | To Check the coating thickness of any coated material such as HDG, Electro Plating, Zinc Flake, Etc. |

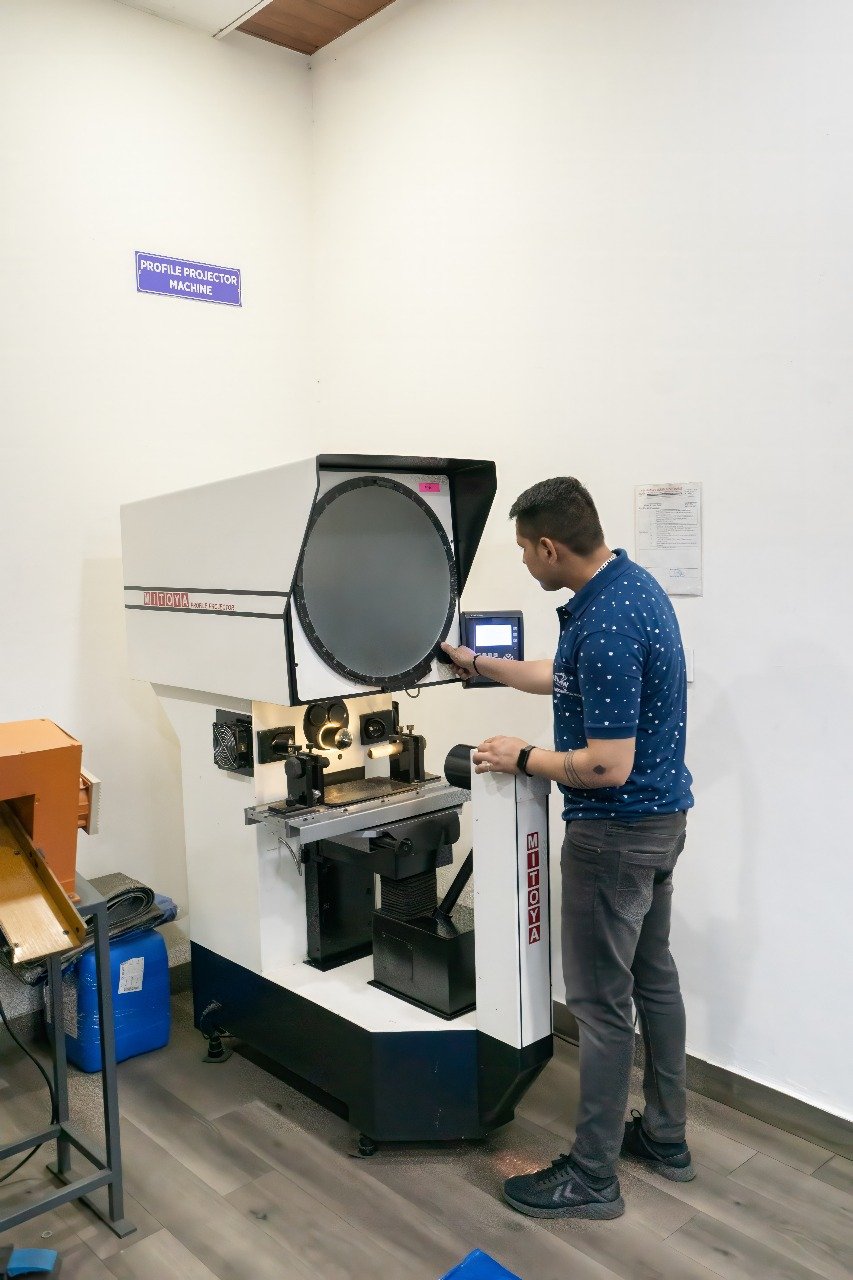

| 09 | Profile Projector | MITUTOYO | X-150mm,Y-150mm/ Ang.-360 | To Measure The Horizontal or Vertical Dimensions, Angles, Root Radius, Depth, Etc. |

| 10 | Magnetic Crack Detector | FLAWCHECK DEFECTOSCOPE | 0-3000 Amp.(AC) | To check the surface discontinuity such as Cracks on by performing Magnetic Particle Inspection. |

| 11 | Feeler Gauge | ATUL | 0.03-1 mm | To measure the gaps in assembly or in any component. |

| 12 | Digital External Micrometer | BAKER | 0-25 mm | To check the diameter , width, thickness of any article. |

| 13 | Hardening Furnace | QTE | 800 X mm | To Hard and Quench any material to achieve the initial desired Physical Property |

| 14 | Tempering Furnace | QTE | 800 X 300 mm & 1600 X 2800 mm | To Temper any material subsequent of Hardening process for relieving the stress to achieve the desired Physical Property such as Tensile strength, Hardness, etc. |

| 15 | Continuous Hardening Furnace | QTE | 2750 X 695 X 100 mm | To Hard and Quench any material in continues form to achieve the initial desired Physical Property. |

| 16 | Continuous Tempering Furnace | QTE | 4100 x 695 x 100 mm | To Temper any material subsequent of Hardening process for relieving the stress to achieve the desired Physical Property such as Tensile strength, Hardness, etc. |

| 17 | Rotary Furnace | MD ENTERPRISES | 68 X 68 mm | To Hard and Quench any material to achieve the initial desired Physical Property |

| 18 | Electronic Extensometer | FIE | Upto 10.00 mm | To evaluate the yield strength under the criteria of Physical Property Testing performed on UTM Machine. |

UNIVERSAL TESTING MACHINE WITH ELECTRONIC EXTENSOMETER

PROFILE PROJECTOR

DIGITAL & MANUAL ROCKWELL HARDNESS TESTER